| Availability: | |

|---|---|

| Quantity: | |

PVC

CANLON

General Description

Based on latest formulation and made of UV-resistant polyvinyl chloride resin that is mixed together with appropriate portion of plasticizer, aging agent, heat-stabilizers, filling agent and other auxiliary agents, CANLON PVC Roofing Membrane are molded by means of high-end one-time extruding technology and its thermoplasticity allows itself to be hot-air weldable, delivering a pliable and durable sheet with excellent weathering characteristics and resistance to harsh chemicals and industrial pollutants.

\

\

Specification

Type | Application | Thickness(mm) | Color | Available Sizes(m) |

Fleece Backed(FB) | Fully Adhered | 1.2/1.5/2.0 | Light Grey | 20mx2.0m(with single selvedge) 20mx2.0m(with double selvedge) |

Fiber Reinforced(FR) | Mechanically Fixed | 1.2/1.5/2.0 | Light Grey | 20m x2.0m |

Smooth(SM) | Fully Adhered | 1.2/1.5/2.0 | Light Grey | 20m x2.0m |

1.Attachment

PVC coated metal,dark grey, in sheets, formed drip edges, water-checks, flashing profiles etc.

2.Adhesives & Sealants

3.Outlets, Vents, Standing Seam Profiles, Solar Fixing Profiles, Lightning Conductor Clips, Rooflights

4.Ancillary Products

Thermal insulation,Vapour Control or Vapour Barrier membranes.

Waterproofing to exposed roofs of industrial and residential buildings.

Waterproofing to exposed single ply light-steel roofs.

Rooting-resistant and puncture-resistant waterproofing layer for planted roofs (ceilings).

Old roof refurbishment.

Application Method: mechanically fastened, adhered.

Cost effective.

Reliable and rapid installation, subject to less climate changes.

Special ancillary accessories are compatible with various substrates, perfect fastened system ensure secure seam and integrity.

Withstand against strong wind negative pressure, so that keep the whole system in safety.

Reinforced membrane effectively avoids any crack around the pinholes.

Notice

Keep the welded area to be clean and free from waterdrop and oil taint.

Before installation shall do trail welding test to determine suitable welding temperature and machine moving speed.

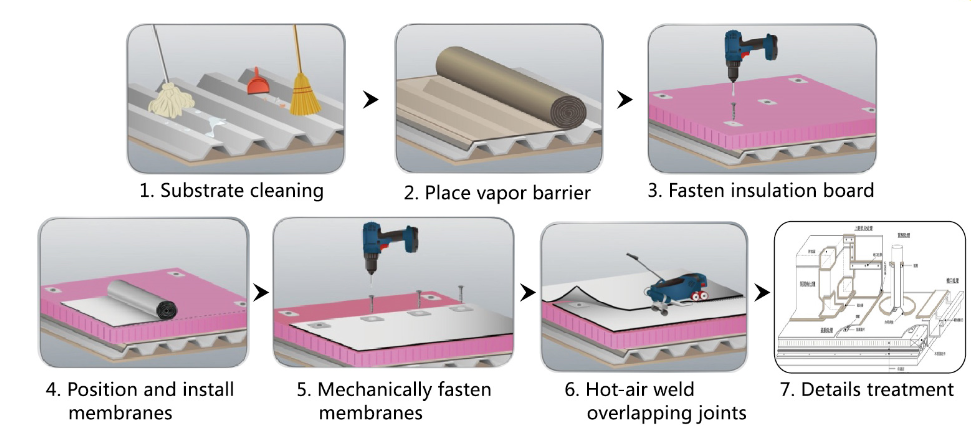

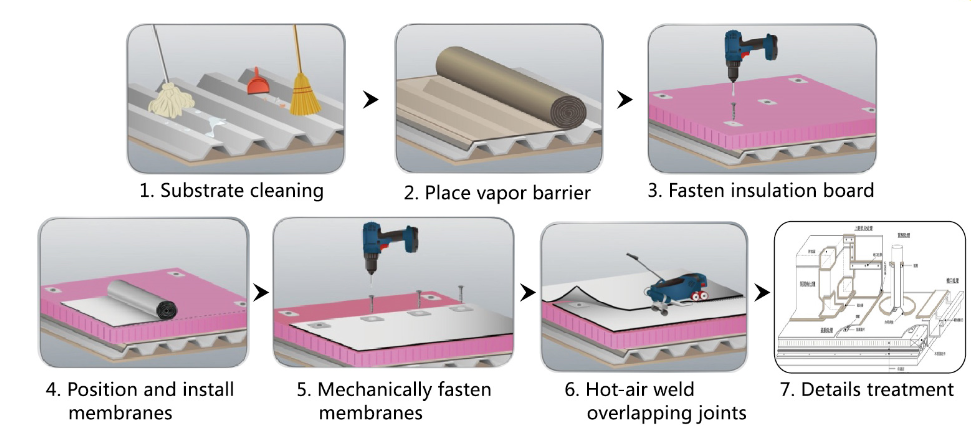

Installation

Mechanically Fastened :

Mechanically attached system is best choice when weight is a consideration, when the system is to be installed during cooler weather or when a roof is being re-covered. Mechanically fastened system is also an optimal choice for steel roof, especially when installing a new roofing system over a structural standing seam metal building, as the mechanical attachment is light weight and less likely to overload the highly engineered weight limits of the building. Wood and cementitious wood fiber are also very suitable decks for mechanically fastened systems. Special fastening accessories machines are indispensable (such as automatic welding machines, hand-held guns and rollers) to secure the whole installation, the overlap joints will be welded by automatic hot-air machines so as to enhance the wind force loading capacity.

Technical Data Sheet

| No. | Essential Characteristics | Harmonised Technical Specification | Performance | ||

CANLON FB | CANLON FR | CANLON SM | |||

| 1 | Watertightness | EN 1928:2001 | Passed | Passed | Passed |

| 2 | Mass per Unit Area | EN 1849-2:2001 | 2240 g/m2 | 2206 g/m2 | 2059 g/m2 |

| 3 | Reaction to Fire | EN13501-1+A1:2009 | Class E | Class E | Class E |

| 4 | Joint Peel Resistance | EN 12316-2:2013 | Av 566 N/50mm | Av710N/50mm | Av 538 N/50mm |

| 5 | Joint Shear Resistance | EN 12317-2:2010 | Av1200N | Av 1526N | Av 10 84N |

| 6 | Tensile Strength in Longitudinal Direction | EN 12311-2:2013 | Av 1360 N/50mm | Av 1696 N/50mm | Av 1425 N/50mm |

| 7 | Tensile Strength in Transverse Direction | EN 12311-2:2013 | Av 1234 N/50mm | Av 1545 N/50mm | Av 1511 N/50mm |

| 8 | Elongation at Rupture- Longitudinal Direction | EN 12311-2:2013 | Av 320% | Av 28% | Av 409% |

| 9 | Elongation at rupture -Transverse Direction | EN 12311-2:2013 | Av 316% | Av 24% | Av 385% |

| 10 | Resistance to Impact | EN 12691:2006 | 0.80m | 0.90m | 0.80m |

| 11 | Resistance to Static Loading | EN 12730:2001 | 20 kg | 20 kg | 20 kg |

| 12 | Tear Resistance- Longitudinal Direction | EN 12310-2:2001 | Av 539 N | Av 643N | Av 301 N |

| 13 | Tear Resistance- Transverse Direction | EN 12310-2:2001 | Av 399 N | Av 690N | Av 296 N |

| 14 | Foldability at low temperature | EN 495-5:2013 | -35℃ | -30℃ | -35℃ |

| 15 | UV Radiation | EN 1297:2004 | Grade 0 no cracks or crazes | Grade 0 no cracks or crazes | Grade 0 no cracks or crazes |

| 16 | External Fire Exposure | BS 476 pt3:2004 | EXT F.AB | EXT F.AB | EXT F.AB |

General Description

Based on latest formulation and made of UV-resistant polyvinyl chloride resin that is mixed together with appropriate portion of plasticizer, aging agent, heat-stabilizers, filling agent and other auxiliary agents, CANLON PVC Roofing Membrane are molded by means of high-end one-time extruding technology and its thermoplasticity allows itself to be hot-air weldable, delivering a pliable and durable sheet with excellent weathering characteristics and resistance to harsh chemicals and industrial pollutants.

\

\

Specification

Type | Application | Thickness(mm) | Color | Available Sizes(m) |

Fleece Backed(FB) | Fully Adhered | 1.2/1.5/2.0 | Light Grey | 20mx2.0m(with single selvedge) 20mx2.0m(with double selvedge) |

Fiber Reinforced(FR) | Mechanically Fixed | 1.2/1.5/2.0 | Light Grey | 20m x2.0m |

Smooth(SM) | Fully Adhered | 1.2/1.5/2.0 | Light Grey | 20m x2.0m |

1.Attachment

PVC coated metal,dark grey, in sheets, formed drip edges, water-checks, flashing profiles etc.

2.Adhesives & Sealants

3.Outlets, Vents, Standing Seam Profiles, Solar Fixing Profiles, Lightning Conductor Clips, Rooflights

4.Ancillary Products

Thermal insulation,Vapour Control or Vapour Barrier membranes.

Waterproofing to exposed roofs of industrial and residential buildings.

Waterproofing to exposed single ply light-steel roofs.

Rooting-resistant and puncture-resistant waterproofing layer for planted roofs (ceilings).

Old roof refurbishment.

Application Method: mechanically fastened, adhered.

Cost effective.

Reliable and rapid installation, subject to less climate changes.

Special ancillary accessories are compatible with various substrates, perfect fastened system ensure secure seam and integrity.

Withstand against strong wind negative pressure, so that keep the whole system in safety.

Reinforced membrane effectively avoids any crack around the pinholes.

Notice

Keep the welded area to be clean and free from waterdrop and oil taint.

Before installation shall do trail welding test to determine suitable welding temperature and machine moving speed.

Installation

Mechanically Fastened :

Mechanically attached system is best choice when weight is a consideration, when the system is to be installed during cooler weather or when a roof is being re-covered. Mechanically fastened system is also an optimal choice for steel roof, especially when installing a new roofing system over a structural standing seam metal building, as the mechanical attachment is light weight and less likely to overload the highly engineered weight limits of the building. Wood and cementitious wood fiber are also very suitable decks for mechanically fastened systems. Special fastening accessories machines are indispensable (such as automatic welding machines, hand-held guns and rollers) to secure the whole installation, the overlap joints will be welded by automatic hot-air machines so as to enhance the wind force loading capacity.

Technical Data Sheet

| No. | Essential Characteristics | Harmonised Technical Specification | Performance | ||

CANLON FB | CANLON FR | CANLON SM | |||

| 1 | Watertightness | EN 1928:2001 | Passed | Passed | Passed |

| 2 | Mass per Unit Area | EN 1849-2:2001 | 2240 g/m2 | 2206 g/m2 | 2059 g/m2 |

| 3 | Reaction to Fire | EN13501-1+A1:2009 | Class E | Class E | Class E |

| 4 | Joint Peel Resistance | EN 12316-2:2013 | Av 566 N/50mm | Av710N/50mm | Av 538 N/50mm |

| 5 | Joint Shear Resistance | EN 12317-2:2010 | Av1200N | Av 1526N | Av 10 84N |

| 6 | Tensile Strength in Longitudinal Direction | EN 12311-2:2013 | Av 1360 N/50mm | Av 1696 N/50mm | Av 1425 N/50mm |

| 7 | Tensile Strength in Transverse Direction | EN 12311-2:2013 | Av 1234 N/50mm | Av 1545 N/50mm | Av 1511 N/50mm |

| 8 | Elongation at Rupture- Longitudinal Direction | EN 12311-2:2013 | Av 320% | Av 28% | Av 409% |

| 9 | Elongation at rupture -Transverse Direction | EN 12311-2:2013 | Av 316% | Av 24% | Av 385% |

| 10 | Resistance to Impact | EN 12691:2006 | 0.80m | 0.90m | 0.80m |

| 11 | Resistance to Static Loading | EN 12730:2001 | 20 kg | 20 kg | 20 kg |

| 12 | Tear Resistance- Longitudinal Direction | EN 12310-2:2001 | Av 539 N | Av 643N | Av 301 N |

| 13 | Tear Resistance- Transverse Direction | EN 12310-2:2001 | Av 399 N | Av 690N | Av 296 N |

| 14 | Foldability at low temperature | EN 495-5:2013 | -35℃ | -30℃ | -35℃ |

| 15 | UV Radiation | EN 1297:2004 | Grade 0 no cracks or crazes | Grade 0 no cracks or crazes | Grade 0 no cracks or crazes |

| 16 | External Fire Exposure | BS 476 pt3:2004 | EXT F.AB | EXT F.AB | EXT F.AB |

Copyright 2024 Jiangsu Canlon Building Materials Co.,Ltd. All Rights Reserved. 苏ICP备11076726号-3