| Availability: | |

|---|---|

| Quantity: | |

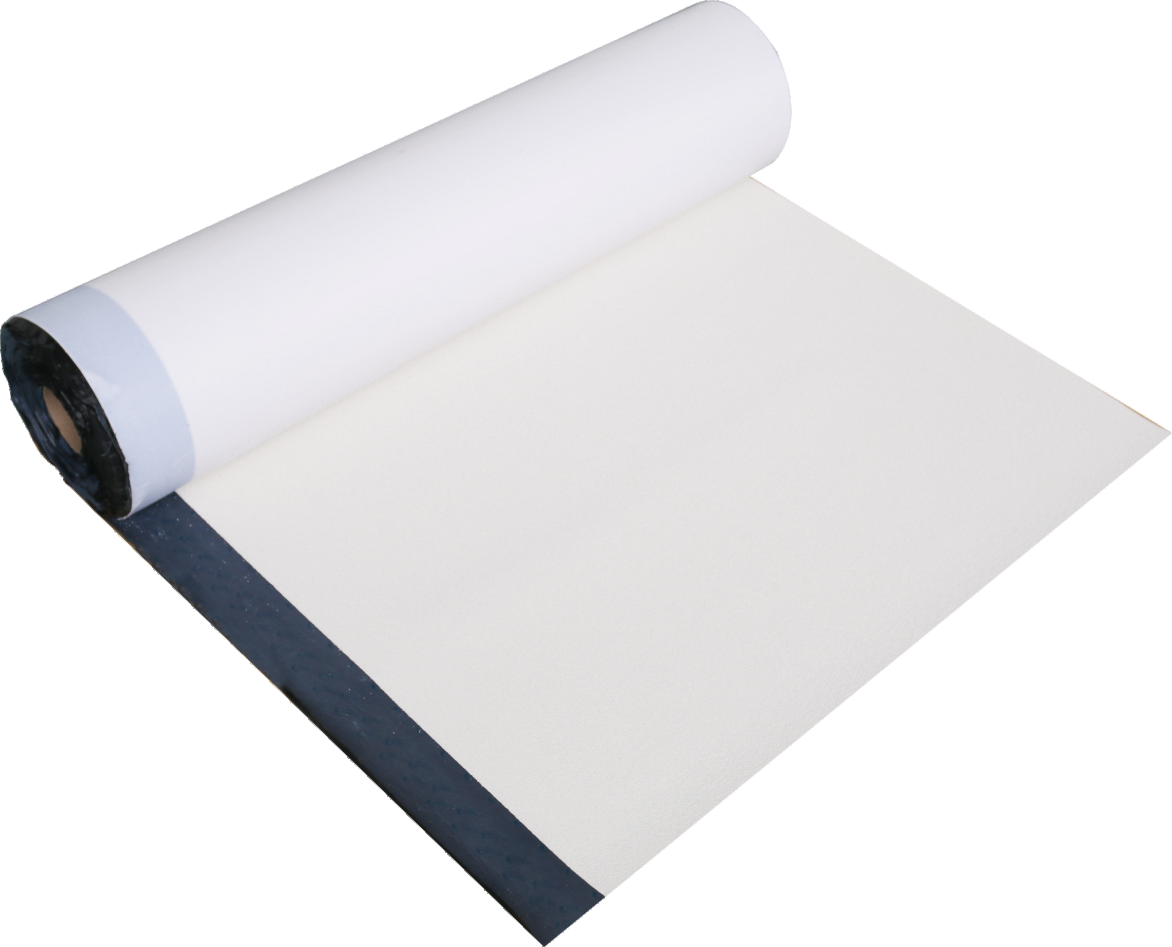

MBP-P

Canlon

MBP-P pre-applied waterproofing membrane

Description

CANLON MBP-P pre-applied waterproofing membrane (Migration Barrier Product) composed of synthetic polymer sheet (HDPE or TPO), pressure sensitive adhesive and weather resistant granular layer. The pre-applied method of construction can be integrated with the concrete structures. Under pressure, the pressure sensitive adhesive and the uncoagulated cement slurry in the post-poured concrete penetrate the anti-stick layer through creep, forming an effective interpetual bond and a huge intermolecular force. After the concrete is cured, the gap between the MBP-P pre-applied waterproofing membrane and the structure is sealed to the greatest extent, eliminating the water migration channel.

Types

According to the different overlapping ways on side laps, it can be divided into self-adhesive type and welding type.

Specifcation

| Thickness(mm) | Sheet Thickness(mm) | Width(m) | Length(mm) |

1.2 | ≥0.7 | lor2 | 20 |

1.5 | ≥1.0 | 1 or 2 | 20 |

1.7 | ≥1.2 | 1or 2 | 15 or 20 |

Product Features

1. White Sheet, Easy to ldentify

If the sheet made from inferior materials such as recycled materials (powder), it is inevitable to be doped with a large number of impurities and wary incolor. CANLON uses pure white virgin chips as raw material, and the sheet is pure white, which is easily to identify.

2. Good Self-adhesive Bonding Perfomance

Pressure sensitive adhesive is well adhered at the beginning,with sufficient cohesion and high peeling strength.

3. Excellent Weather Resistance

Anti-stick particles are synthetic sand treated by special processes such as calcification, which are resistant to aging and powdering. While avoiding sticking to the feet, it ensures the performance of the membrane bonding with concrete at job sites. The membrane has undergone a maximum of 49 days of environmental impact (stampede pollution,sun exposure and water,etc.),but the performance remains unchanged.

4. Good Dimensional Stability

Under the on-site sun exposure, the wrinkle degreeof membrane is light, which is far better than that of similar products according to national standard.

5. Corosion Resistant

Passed the "acid, alkali, salt" test of the National Building Materials Testing Center, and the membrane perormance is almost unaffected in the general saline alkali land or acid rain area.

Application Features

1. Reliable Quality

The membrane and concrete structures are integrated to compensate for possible defects, thereby greatly reducing the probability of leakage.

2. Shorten Construction Period

Compared with the traditional practice, the low requirements for the substrate, the basic weather impact, coupled with the simplification of the structure, can shorten the construction period by more than 18 days.

3. Low System Cost

When waterproofing and fortification of the same level, the simplified structure can reduce the cost of the system by about 30%, and the leakage rate is low, which can reduce the cost of later maintenance.

4. Safe and Environmentally Friendly

No primer and open flame operation is required to avoid hazards and eliminate security risks, but also save resources.

Application

1. Waterproofing to the foundation underslab & blind side wall of the industrial and civilbuilding.

2. Undergrund waterproofing ofsubways,nuclear power plants, urban utility tunnels, open-cut tunnels, and under-cut tunnels.

3. Other undergrund projects,especially suitablefor pre-applied waterproofing parts.

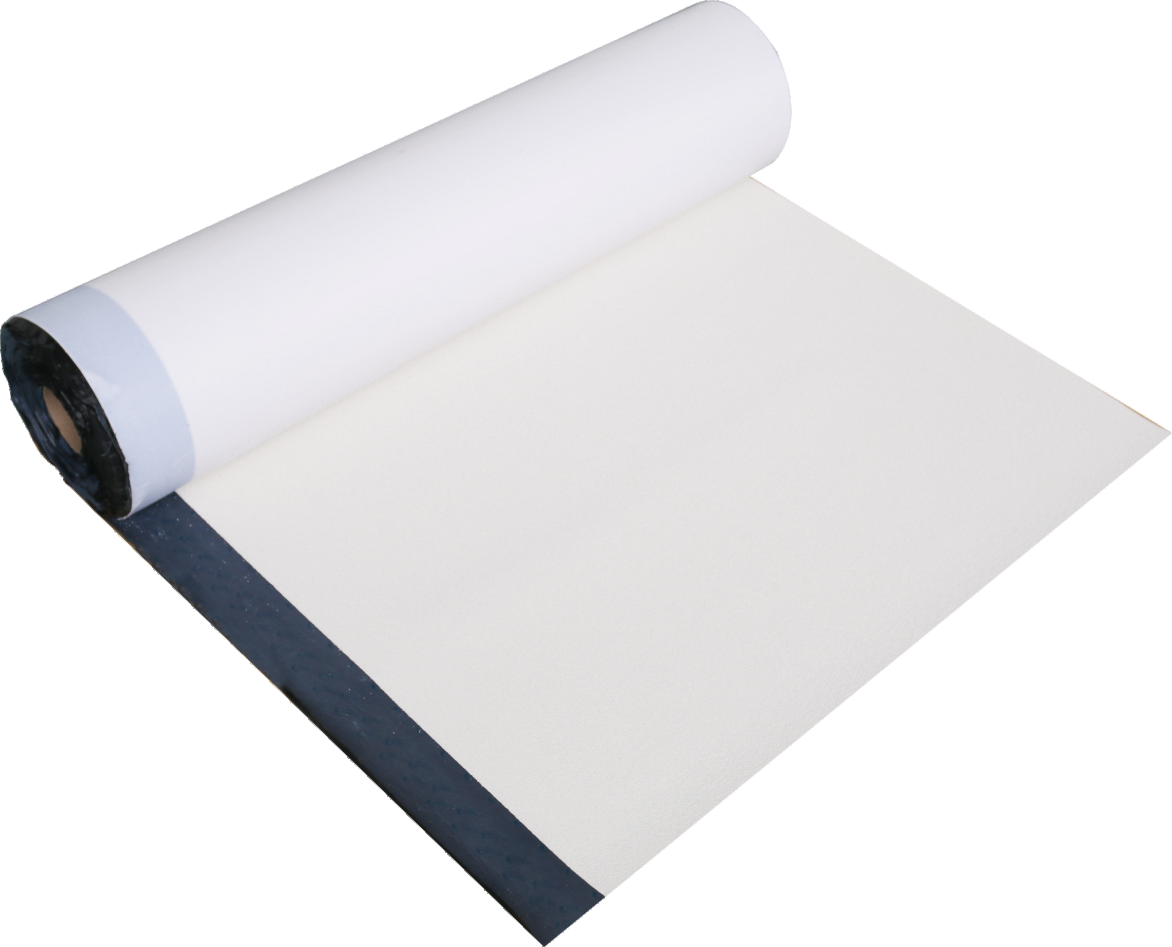

MBP-P pre-applied waterproofing membrane

Description

CANLON MBP-P pre-applied waterproofing membrane (Migration Barrier Product) composed of synthetic polymer sheet (HDPE or TPO), pressure sensitive adhesive and weather resistant granular layer. The pre-applied method of construction can be integrated with the concrete structures. Under pressure, the pressure sensitive adhesive and the uncoagulated cement slurry in the post-poured concrete penetrate the anti-stick layer through creep, forming an effective interpetual bond and a huge intermolecular force. After the concrete is cured, the gap between the MBP-P pre-applied waterproofing membrane and the structure is sealed to the greatest extent, eliminating the water migration channel.

Types

According to the different overlapping ways on side laps, it can be divided into self-adhesive type and welding type.

Specifcation

| Thickness(mm) | Sheet Thickness(mm) | Width(m) | Length(mm) |

1.2 | ≥0.7 | lor2 | 20 |

1.5 | ≥1.0 | 1 or 2 | 20 |

1.7 | ≥1.2 | 1or 2 | 15 or 20 |

Product Features

1. White Sheet, Easy to ldentify

If the sheet made from inferior materials such as recycled materials (powder), it is inevitable to be doped with a large number of impurities and wary incolor. CANLON uses pure white virgin chips as raw material, and the sheet is pure white, which is easily to identify.

2. Good Self-adhesive Bonding Perfomance

Pressure sensitive adhesive is well adhered at the beginning,with sufficient cohesion and high peeling strength.

3. Excellent Weather Resistance

Anti-stick particles are synthetic sand treated by special processes such as calcification, which are resistant to aging and powdering. While avoiding sticking to the feet, it ensures the performance of the membrane bonding with concrete at job sites. The membrane has undergone a maximum of 49 days of environmental impact (stampede pollution,sun exposure and water,etc.),but the performance remains unchanged.

4. Good Dimensional Stability

Under the on-site sun exposure, the wrinkle degreeof membrane is light, which is far better than that of similar products according to national standard.

5. Corosion Resistant

Passed the "acid, alkali, salt" test of the National Building Materials Testing Center, and the membrane perormance is almost unaffected in the general saline alkali land or acid rain area.

Application Features

1. Reliable Quality

The membrane and concrete structures are integrated to compensate for possible defects, thereby greatly reducing the probability of leakage.

2. Shorten Construction Period

Compared with the traditional practice, the low requirements for the substrate, the basic weather impact, coupled with the simplification of the structure, can shorten the construction period by more than 18 days.

3. Low System Cost

When waterproofing and fortification of the same level, the simplified structure can reduce the cost of the system by about 30%, and the leakage rate is low, which can reduce the cost of later maintenance.

4. Safe and Environmentally Friendly

No primer and open flame operation is required to avoid hazards and eliminate security risks, but also save resources.

Application

1. Waterproofing to the foundation underslab & blind side wall of the industrial and civilbuilding.

2. Undergrund waterproofing ofsubways,nuclear power plants, urban utility tunnels, open-cut tunnels, and under-cut tunnels.

3. Other undergrund projects,especially suitablefor pre-applied waterproofing parts.

Copyright 2024 Jiangsu Canlon Building Materials Co.,Ltd. All Rights Reserved. 苏ICP备11076726号-3